Natural cork bark is a material that has fascinated and inspired people for centuries. Thanks to its unique structure, natural properties, and aesthetic appearance, it has found wide applications in many fields—from interior design to the production of everyday items. When we think of cork, we often imagine simple products like bottle stoppers, but this remarkable material has far more to offer.

In this article, we’ll take a closer look at the texture of cork bark, its structure, unique properties, and uses that make it one of the most interesting natural materials available in modern design.

Table of Contents:

1. Introduction

2. What does cork bark look like? — Texture and details

3. Anatomy of cork bark — what is it made of?

4. How does cork bark differ from others?

5. Unique properties

6. Summary

7. FAQ

What does cork bark look like? — Texture and details

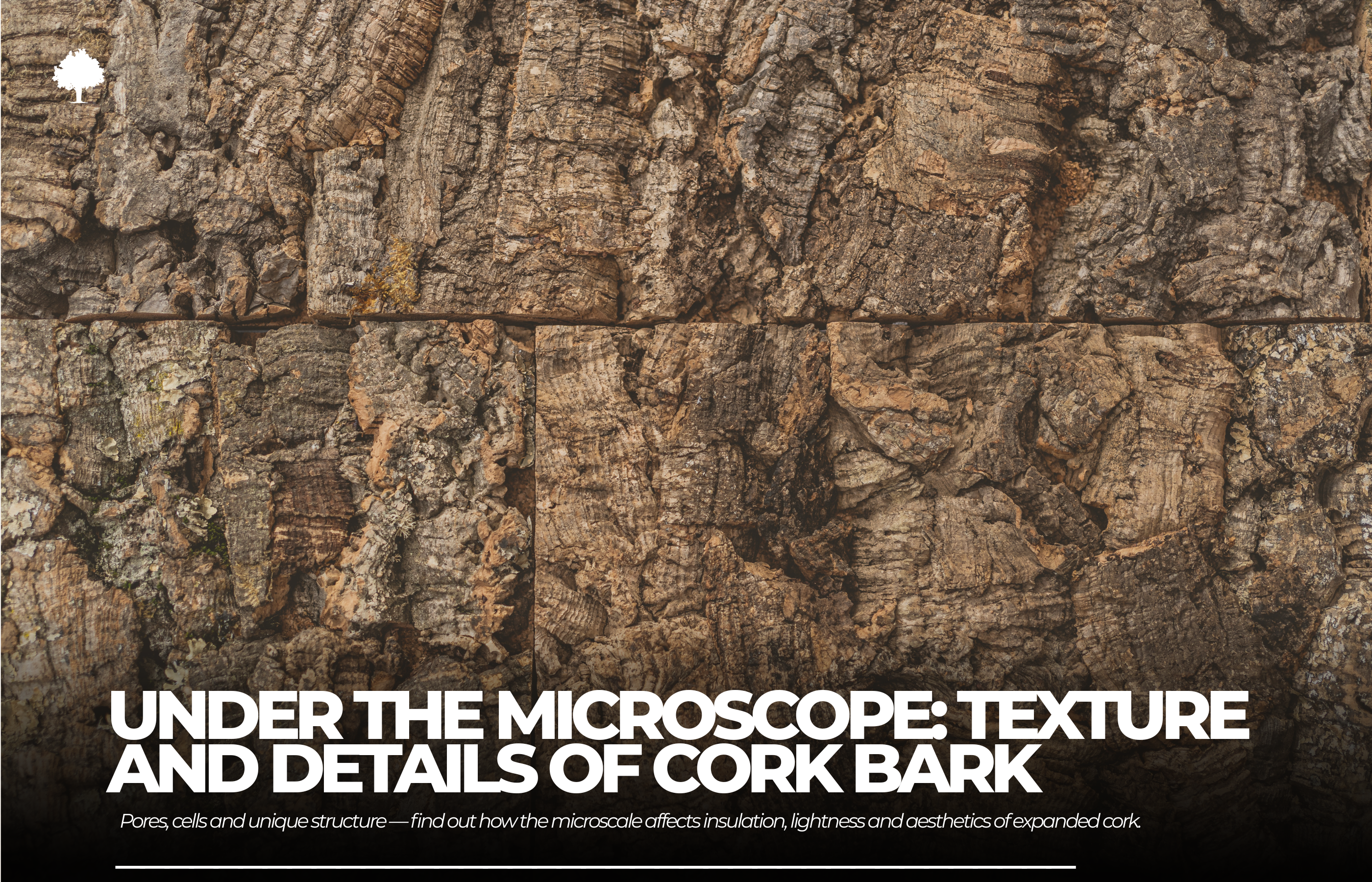

At first glance, cork bark may appear to be a simple, raw material, but in reality, it is visually very intriguing. Its surface is full of unique details that create a distinctive natural pattern. Cork bark is characterized by irregular pores that form a striking, textured surface. Within the bark, you can also see natural lines and patterns created by the processes of growth and harvesting.

Variation depending on age and harvesting method

The appearance of cork bark varies depending on its age and how it was harvested. Younger layers tend to be thinner with a smoother texture. Older bark, taken from more mature trees, is thicker and shows a more complex surface. Cork bark harvested using traditional methods, without mechanical tools, retains an even more natural look, often marked by fine cracks and irregular air pockets.

Microscopic details: what does cork look like under magnification?

When viewed under a microscope, cork reveals a fascinating world of microscopic details. Its structure resembles a complex network of cells that form hollow spaces filled with air. These microstructures are responsible for many of cork’s unique qualities, such as lightness, flexibility, and insulation. Under magnification, the irregular arrangement of the cells and the porous structure become clear—features that make cork such a versatile and exceptional material.

Anatomy of cork bark — what is it made of?

Cellular composition: suberin, lignin, cellulose, waxy substances

Cork bark has a complex cellular structure that gives it its distinctive properties. Its main components are suberin, lignin, cellulose, and waxy substances. Suberin is one of the most important elements, providing a protective layer and water resistance. This makes cork highly resistant to moisture and weather changes. Lignin, though present in smaller amounts, reinforces the structure, adding strength. Cellulose provides flexibility and durability, while the waxy substances on the bark’s surface protect it from moisture loss and contamination.

How does the cell structure affect its properties?

The cellular structure of cork bark is what gives it its remarkable qualities. It consists of small, tightly packed cells that form air-filled cavities. This special structure makes cork extremely lightweight despite its strength. Its lightness makes it an excellent material for various applications, from flooring to insulation.

Cork’s flexibility comes from its ability to return to its original shape after compression. This phenomenon, often called "shape memory," makes cork exceptionally durable, as it resists permanent deformation under pressure—a key reason why it’s used in furniture and flooring.

Thanks to its cellular structure, cork is also highly water-resistant. Suberin and the specific microstructure of its cells allow cork bark to repel water effectively, making it ideal for use in damp environments.

The role of hollow cell spaces (up to 90% of its volume!)

One of the most important aspects of cork bark’s structure is the presence of hollow cell spaces, which make up as much as 90% of its volume. These air-filled cavities give cork its lightness as well as excellent thermal and acoustic insulation. This unique feature not only makes cork extremely lightweight but also allows it to absorb sound and vibrations, making it an ideal material for construction and furniture industries. In addition, these spaces give cork its ability to "breathe," helping maintain a healthy indoor climate wherever it’s used.

How does cork bark differ from other tree barks?

Cork bark vs oak, birch, and pine bark

Cork bark stands out from other types of tree bark because of its unique cellular structure and properties. While oak, birch, and pine bark also serve protective functions for trees, their structures are not suitable for producing cork, which requires special characteristics such as lightness, flexibility, and water resistance.

Oak bark, although hard and durable, lacks the porous structure that makes cork so light and insulating. It is heavier, less flexible, and does not provide the same level of moisture protection, which makes it unsuitable for applications such as insulation or acoustic materials.

Birch and pine bark, on the other hand, are much thinner, and their cells do not contain enough air-filled cavities that give cork its properties. While these barks have their uses—especially in furniture making or crafts—they do not meet the requirements expected of insulating or cushioning materials.

Why can’t other barks be used as cork substitutes?

Cork bark has a one-of-a-kind structure that makes it perfect for a wide range of applications, from flooring to accessories. Its defining feature is the presence of air cells in its structure. These hollow spaces make cork extremely lightweight, insulating, and resistant to moisture. In other types of bark, such as oak, birch, or pine, the cellular structure is far less developed, and the cells are denser, which limits their insulating and flexible properties.

Cork bark is also naturally resistant to fire, mold, and fungi, thanks to its complex chemical composition, including suberin, which protects it against harsh weather conditions. While other barks may be relatively durable, they do not offer the same protective features.

The myth of “cork substitutes” — what’s true and what’s marketing?

More and more products are being advertised as “cork substitutes.” However, it’s important to remember that no material can fully replicate the properties of cork bark. Manufacturers of these alternatives often highlight that they are more eco-friendly or cheaper to produce, but many of these claims are not fully supported by facts.

In reality, while some materials may mimic the appearance of cork, they do not provide the same level of lightness, flexibility, water resistance, and insulation. Alternatives such as synthetic substitutes are often not biodegradable—unlike natural cork, which is both fully renewable and eco-friendly. Moreover, cork’s natural properties—its structure, resistance to fungi, mold, and water—are difficult to reproduce in artificial materials.

It’s also worth emphasizing that cork comes from sustainable and renewable sources—cork oak trees can be harvested without cutting them down, making the process both sustainable and environmentally friendly. Many materials marketed as cork alternatives cannot compete with it in terms of sustainability or complete biodegradability.

Unique properties — thanks to its texture and structure

Cork bark is a material with exceptionally rich properties, resulting from its unique cellular composition and structure. What sets cork apart from other natural materials is its versatility and outstanding qualities, making it an ideal solution for many applications in both construction and design.

Impermeability to liquids and gases

One of cork bark’s key features is its ability to be completely impermeable to liquids and gases. Thanks to its cellular structure, with air-filled spaces, cork effectively blocks water and various gases, making it extremely resistant to moisture. This property is highly valued in construction, particularly for insulating materials, wall panels, or flooring. Cork is also used in industry where protection from unwanted substances is crucial—for example, in the production of seals and other protective components.

Natural fire resistance

Cork bark is also naturally resistant to fire. Suberin, one of the main chemical components of cork, makes it less flammable and helps slow down the spread of flames. This makes cork an ideal solution in areas where fire safety is a priority, such as insulation panels in residential and commercial buildings. In addition, cork does not release toxic gases when burning, making it a safer choice compared to many other building materials.

Resistance to fungi, mold, and insects

Cork bark also shows remarkable resistance to fungi, mold, and insect damage. Thanks to its specific chemical composition and the presence of waxy substances on the surface, cork does not support the growth of microorganisms that could cause deterioration. This makes it an ideal material for use in damp spaces such as bathrooms, basements, or areas exposed to changing climate conditions.

Exceptional resilience and shape memory

The cellular structure of natural cork, filled with air, gives the material remarkable elasticity. This means it can return to its original form after being compressed or crushed—especially valuable in applications that demand resistance to pressure, such as flooring or wall panels. Its shape memory makes natural cork exceptionally durable, with a structure that resists permanent deformation even after long-term use.

Warmth and softness to the touch — user perceptions

Cork bark also feels pleasant, offering warmth and softness that enhance the user experience. Unlike some other natural materials that feel cool to the touch, it provides a sense of a warm, cushioned surface—making it an ideal choice for floors, wall panels, and a variety of interior accessories.

Applications of cork bark

Thanks to all these properties, natural cork is used to make a wide range of products. Cork bark is crafted into wall panels that, with their thermal and acoustic insulation, work perfectly in spaces where sound comfort is important. It is also used in flooring that combines functionality with aesthetics, offering warmth and comfort underfoot. In addition, natural cork lends itself to various accessories—such as bags, wallets, and decorative elements—that are not only durable but also environmentally friendly.

Summary

Cork bark is a material with an unmistakable texture and detailing that define its uniqueness. Irregular pores, distinctive lines, and its natural grain make it highly aesthetic and photogenic—ideal for interior design and décor. Variations in appearance depending on age and harvesting method add even more character, creating one-of-a-kind patterns that captivate in both large surfaces and small details.

FAQ

1. What is cork and where does it come from?

Natural cork comes from the bark of the cork oak (Quercus suber), which grows mainly in Mediterranean regions. These trees regenerate their bark, allowing for cyclical harvesting without cutting the tree down.

2. What does the cork bark harvesting process look like?

Cork bark is traditionally harvested every 9–12 years. To avoid damaging the tree, the bark is removed by hand, which allows it to regenerate naturally. The tree remains unharmed, and the bark grows back, making future harvests possible.

3. Why is cork so light?

Natural cork is exceptionally lightweight thanks to its unique cellular structure, composed largely of hollow, air-filled spaces. This porosity delivers remarkable lightness while maintaining strength and durability.

4. Is cork an eco-friendly material?

Yes, natural cork is fully eco-friendly. It comes from renewable resources (cork oaks are not felled), is biodegradable, and can be reused. Moreover, harvesting does not involve cutting down trees, helping to maintain healthy forest ecosystems.