LISEC is a brand recognized worldwide among glass manufacturers. Founded in 1961 in Austria, the company has been setting standards for decades in the processing, cutting, and automation of flat glass production. Its solutions are at the heart of modern glass processing plants—from precision machinery to comprehensive software for managing production lines.

But what do natural cork and foam have to do with all this? In this article, we take a closer look at this unexpected connection.

Table of Contents

1. Introduction

2. What links natural cork-foam tape and LISEC?

3. Glass under protection – challenges in transporting and storing sheets

4. How does natural cork-foam tape fit LISEC’s philosophy?

5. Practical applications

6. Why it pays off

7. Summary

8. FAQ

What links natural cork-foam tape and LISEC?

The answer is simple—glass. It is the common denominator between LISEC’s advanced technologies and the seemingly simple yet crucial component that is natural cork-foam tape. Both solutions operate in the same realm—the world of precision, delicacy, and constant commitment to quality.

LISEC – a leader in glass processing automation

LISEC is a global authority in automated glass processing. For more than sixty years, the company has been creating comprehensive systems that cover every stage of production—from cutting and sorting, through edge processing, to assembling insulating glass units.

Thanks to continuous investment in research and development, LISEC sets the benchmarks for quality and efficiency that the entire industry looks to. Its machines and software are designed to deliver maximum precision while minimizing material waste—crucial advantages in the world of glass.

The company’s philosophy centers on automation, reliability, and product protection, making it not only a technology supplier but also a partner in the pursuit of perfection. LISEC understands that every microcrack, scratch, or misaligned sheet can undermine the entire production process—so each innovation serves a single goal: protect the glass and elevate the quality of the final result.

This is exactly where natural cork-foam tape comes in—an unassuming yet highly effective element that serves the same mission as LISEC’s systems: ensuring the glass remains flawless.

Glass under protection – challenges in transporting and storing sheets

Glass is a material that is, on the one hand, robust and resistant, and on the other, extremely delicate. A slight tension, a microcrack, or improper pressure is enough to destroy the value of a perfectly processed sheet. That’s why transporting and storing glass are among the most sensitive stages of the entire production process.

Challenges: microcracks, scratches, losses

After processing is complete, glass sheets are often stacked—one on top of another. Any glass-to-glass contact can lead to scratches, chipping, or microcracks that are not always immediately visible. Over time, such damage may cause breakage during transport, installation, or tempering.

Additionally, separating sheets incorrectly—without adequate spacing and cushioning—increases the risk of material losses and complaints, which, for large glass plants, translates into significant logistics and production costs.

Natural cork-foam tape – a small component with big impact

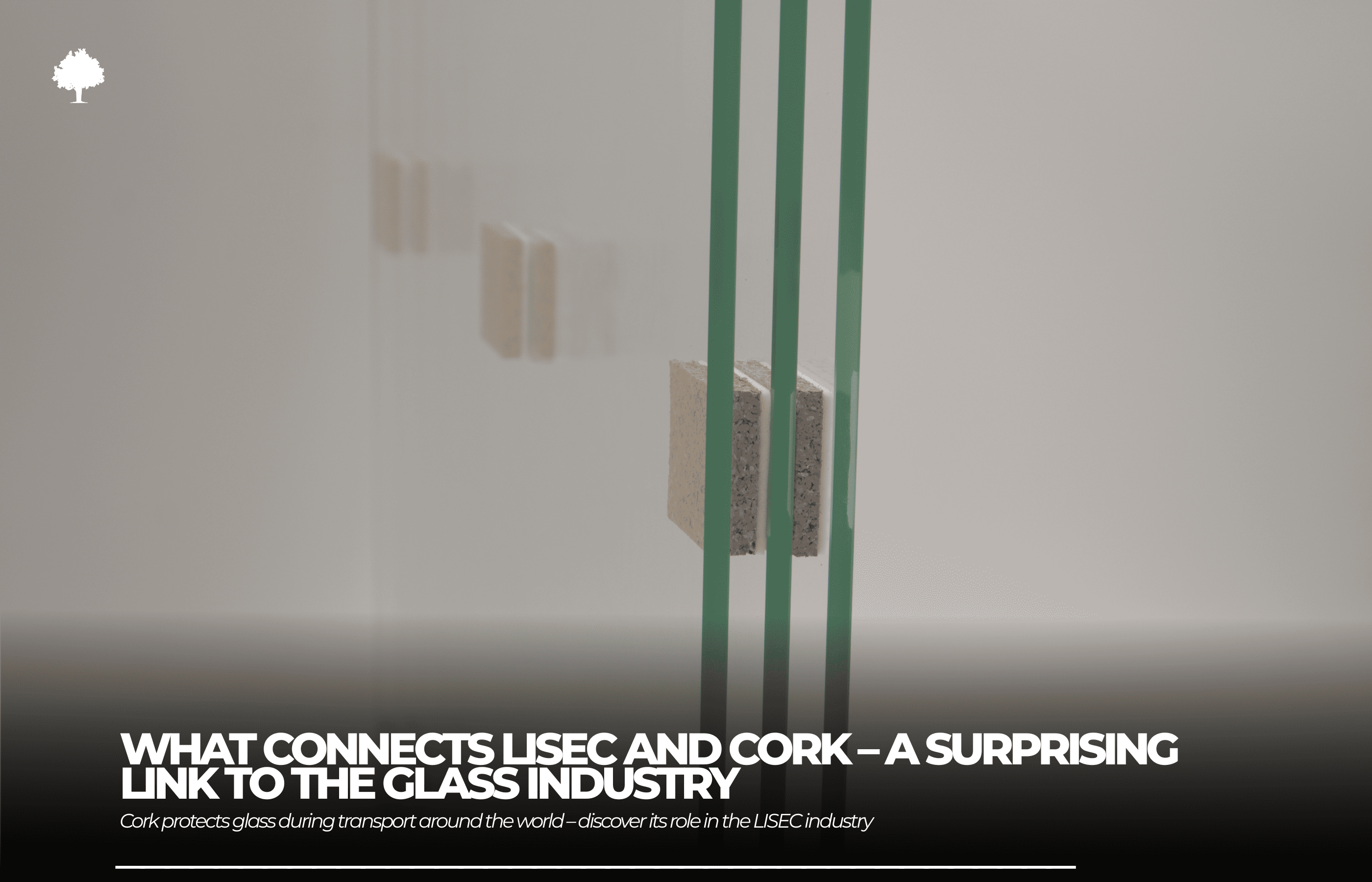

The solution to these challenges is natural cork-foam tape. It’s a small yet remarkably effective component that combines the inherent elasticity of natural cork with the grip of foam.

This specialist natural cork-foam tape, used with a dedicated machine, enables precise cutting into cork spacers of the required dimensions. As a result, production becomes fast, repeatable, and highly accurate, and the finished elements maintain excellent quality and appearance.

Natural cork, thanks to its resilience, absorbs shocks and distributes pressure evenly, protecting the glass surface from point loads. The foam layer, in turn, provides stability and grip, preventing sheets from shifting during transport and storage.

How does natural cork-foam tape fit LISEC’s philosophy?

At first glance, LISEC’s modern production lines and natural cork-foam tape may seem like two different worlds—one represents advanced automation technology, the other a simple mechanical protective element. In reality, they share the same philosophy: automation, precision, and protection.

Automation, precision, protection – shared values

For decades, LISEC has pursued perfection in glass processing. Every machine, every piece of software, and every module in the production line serves one purpose—to minimize the risk of human error and guarantee consistent quality. Natural cork-foam tape follows the same logic. Although it’s not a digital component, its role is equally precise—it prevents accidental damage to sheets at stages that often fall outside automation: transport, storage, and packaging.

A shared goal: a flawless glass sheet

In the glass industry, every millimeter counts. That’s why both LISEC and manufacturers of protective accessories strive for the same goal—preserving a perfect glass sheet. Precise cutting and automated edge processing are the first steps. The next is safeguarding that result from damage during transport and storage.

Combining LISEC’s cutting technology with appropriate protective materials, such as natural cork-foam tape, significantly reduces the risk of microcracks, scratches, and material losses. This makes glass processing not only more efficient but also complete—covering the entire life cycle of the sheet, from the first cut to delivery to the end customer.

Practical applications – where natural cork-foam tape proves useful

Although natural cork-foam tape may look modest, its uses in the glass industry are remarkably broad. It is an integral element of many stages of the production process—from the moment cutting is complete to preparing finished glass for shipment.

Sorting and separation after cutting

After precision cutting, individual glass pieces must be separated and protected from direct contact. This is where natural cork-foam tape plays a key role. Thanks to the foam’s flexibility and grip, spacers keep sheets stable, preventing shifting and rubbing against each other. This minimizes the risk of microcracks and scratches that might only become apparent in later processing stages.

Protection after tempering

After tempering, glass is exceptionally hard but also more brittle at the edges. Using natural cork-foam tape enables safe storage and transport of high-value sheets by cushioning vibrations and distributing pressure at contact points. This is especially important for large formats, where even a minor shock can cause breakage.

Packaging and transport

During packaging and preparation for shipment, natural cork-foam tape serves as a spacer and stabilizer. Its structure maintains equal gaps between sheets, preventing them from shifting inside transport crates or on A-frames.

Storage and display

In many production facilities, the tape is also used in warehouses and quality control areas, where glass is temporarily stored or presented to customers. It allows sheets to be stacked safely without risking surface damage.

Why investing in quality pays off

Fewer complaints and production losses

Using the right protective materials significantly reduces the risk of scratches, cracks, and other defects that often appear only after the product reaches the customer. As a result, the number of complaints decreases, lowering replacement and reproduction costs. High-quality protection safeguards not only the glass but also the manufacturer’s reputation.

Better aesthetics and sheet quality

Premium glass must be not only durable but also perfectly smooth and visually flawless. Even the slightest mark or minor scuff can determine whether a product is accepted. Natural cork-foam tape, thanks to its structure and clean removal without residue, helps maintain glass sheets in pristine condition from processing to final installation.

Improved safety in transport and storage

Transporting and storing glass are among the most challenging stages of production. Vibrations, shocks, and temperature fluctuations all affect its integrity. Using the right separators, such as natural cork-foam tape, greatly reduces the risk of damage and allows safe transport of even the largest glass formats. This translates into tangible logistical savings and fewer material losses along the way.

Summary

At first glance, natural cork-foam tape and LISEC’s advanced systems may seem to belong to two different worlds—one represents precise, automated technology, while the other is a simple, manual protective material. Yet they share a common foundation: glass and the pursuit of its perfection.

For years, LISEC has been setting the direction for the glass industry by delivering machines and software that ensure top-quality processing, process consistency, and production safety. Meanwhile, natural cork-foam tape, though modest in appearance, plays an indispensable role in this chain—it protects the results of human and machine work, ensuring that every sheet of glass reaches the customer in perfect condition.

FAQ

1. Why is natural cork-foam tape so important in the glass industry?

It’s a small but crucial protective component—combining the cushioning properties of natural cork with the grip of foam, it prevents glass sheets from shifting and scratching during transport and storage.

2. How does natural cork-foam tape fit LISEC’s philosophy?

LISEC focuses on precision, automation, and quality protection—the same principles that natural cork-foam tape embodies. Both solutions pursue a single goal: maintaining the perfect condition of glass at every stage of processing and transport.

3. Is investing in natural cork-foam tape really worth it?

Yes. It helps glass manufacturers reduce complaints, minimize material losses, and enhance the visual quality of finished products. In the long term, this leads to real cost savings and strengthens the company’s image as a provider of premium quality.

4. Where is natural cork-foam tape used?

It is most commonly used to separate glass sheets after cutting or tempering, as well as during sorting, packing, and transport. It performs equally well in craft workshops and large, automated production lines.

We will publicly show your name and comment on this website. Your email is to ensure that the author of this post can get back to you. We promise to keep your data safe and secure.