When we talk about thermal or acoustic insulation in buildings, most of us picture the typical solutions: polystyrene boards, mineral wool, or insulation mats. These materials dominate the market and are widely used for insulating walls, roofs, or floors. However, in real construction and renovation work, situations often arise where traditional insulation materials fall short – not because they are of poor quality, but due to their physical limitations.

Recesses, corners, gaps, double walls, or spaces between beams are areas that are hard to reach or simply unsuitable for rigid or large-format insulation materials.

In this guide, we’ll explain why standard insulation doesn’t always work and how to choose the right material for challenging spaces.

Table of Contents

1. Introduction

2. Why is insulating difficult spaces important?

3. What features should effective insulation for hard-to-reach areas have?

4. Solution: Expanded natural cork granules

5. Summary

6. FAQ

Why is the topic of insulating difficult spaces important?

Standard insulation in the form of boards and sheets – advantages and limitations

Traditional insulation materials such as boards or sheets offer many benefits. They are effective, proven, and easy to access. Installation on large, flat surfaces – walls, roofs, or floors – is fast and cost-efficient. Their thermal and acoustic properties help reduce energy loss and improve indoor comfort.

However, the very features that make them ideal in standard situations become a limitation in hard-to-reach areas. Boards are rigid, have a fixed thickness, and cannot be easily shaped to fit unusual forms or tight spaces. Cutting them generates waste, and any lack of precision leads to thermal bridges and air leaks.

Where do they work best?

Standard insulation systems perform best on:

-

large, even surfaces (walls, roofs, floors),

-

buildings with simple shapes and forms,

-

sites with full access to the application area,

-

conditions where no material flexibility is required.

Why doesn’t it work in tight and irregular areas?

Corners and gaps often have irregular shapes, are narrow, and are usually difficult to access. Boards or mats cannot fill them precisely – empty voids remain, creating “weak points” in the insulation system. In such spaces:

-

thermal bridges develop,

-

water vapour condenses, causing moisture issues,

-

the material may shift or collapse over time,

-

acoustic performance of the structure deteriorates.

As a result – even if the main surfaces are well insulated – the entire system loses efficiency.

Spaces that cause problems

Recesses, corners, and gaps

Due to their shapes and dimensions, they are often neglected or poorly insulated.

Double walls and interlayer spaces

In older buildings or layered wall systems, cavities between two structural layers are difficult to insulate using boards. These gaps are a major source of heat loss.

Between floor beams and within ceilings

Spaces between load-bearing beams create insulation challenges. Irregularities or gaps between elements prevent tight placement of rigid materials.

Components of mixes and screeds

In floor insulation and sub-base layers, there is often a need to reduce total weight or improve thermal and vapour-permeability properties. Traditional insulation materials are neither loose fillers nor additives to mortar, so they do not work well in such applications.

What features should effective insulation for difficult spaces have?

Not every type of insulation is suitable for irregular or hard-to-reach spaces. Where standard solutions fail, other material properties become essential – not only thermal conductivity (λ). Effective insulation for gaps, corners, and recesses must meet several key requirements:

Flexibility and adaptability

The primary requirement in difficult spaces is the ability of the material to fill irregular shapes. That’s why loose, free-flowing, or expandable insulation forms are ideal. Such materials:

-

easily conform to tight, hard-to-measure areas,

-

eliminate the risk of leaving empty voids.

Thermal and acoustic performance

Fit alone isn’t enough – the material must also insulate effectively against heat and sound. This means:

-

it should have a low thermal conductivity value (λ),

-

it should absorb airborne and structural noise (such as footsteps, impacts, or sounds from installations),

-

it should be dimensionally stable, resistant to settling or separating over time.

Moisture resistance and vapour permeability are also valuable features, as they help prevent condensation and mould.

Low weight

When filling cavities, interlayer spaces, or adding insulation to mixes, the material’s own weight becomes extremely important. Insulation that is too heavy:

-

can overload the structure, especially in older buildings,

-

is more difficult to apply – particularly in tight construction spaces,

-

is unsuitable as an additive to screeds – because it alters their mechanical properties.

Solution: Expanded Natural Cork Granules

What kind of material is it?

Expanded natural cork granules are an eco-friendly, natural insulation material created by heating cork grains to high temperatures. During this process:

-

the natural cork expands,

-

a natural resin – suberin – is released, binding the grains without any added adhesives or chemicals,

-

a porous material is formed that is extremely lightweight yet durable.

The final product is granules available in different fractions, which can be easily applied in hard-to-reach spaces, blown in, mixed with mortars, or used as a loose insulation layer.

What properties does it have?

Natural cork granules offer all the qualities expected from modern, eco-friendly insulation materials:

-

Excellent thermal insulation.

-

Outstanding acoustic insulation.

-

Low weight.

-

Vapour permeability.

-

Biological resistance: it does not mould, rot, or provide a food source for fungi or insects.

-

Durability.

Examples of applications for natural cork granules

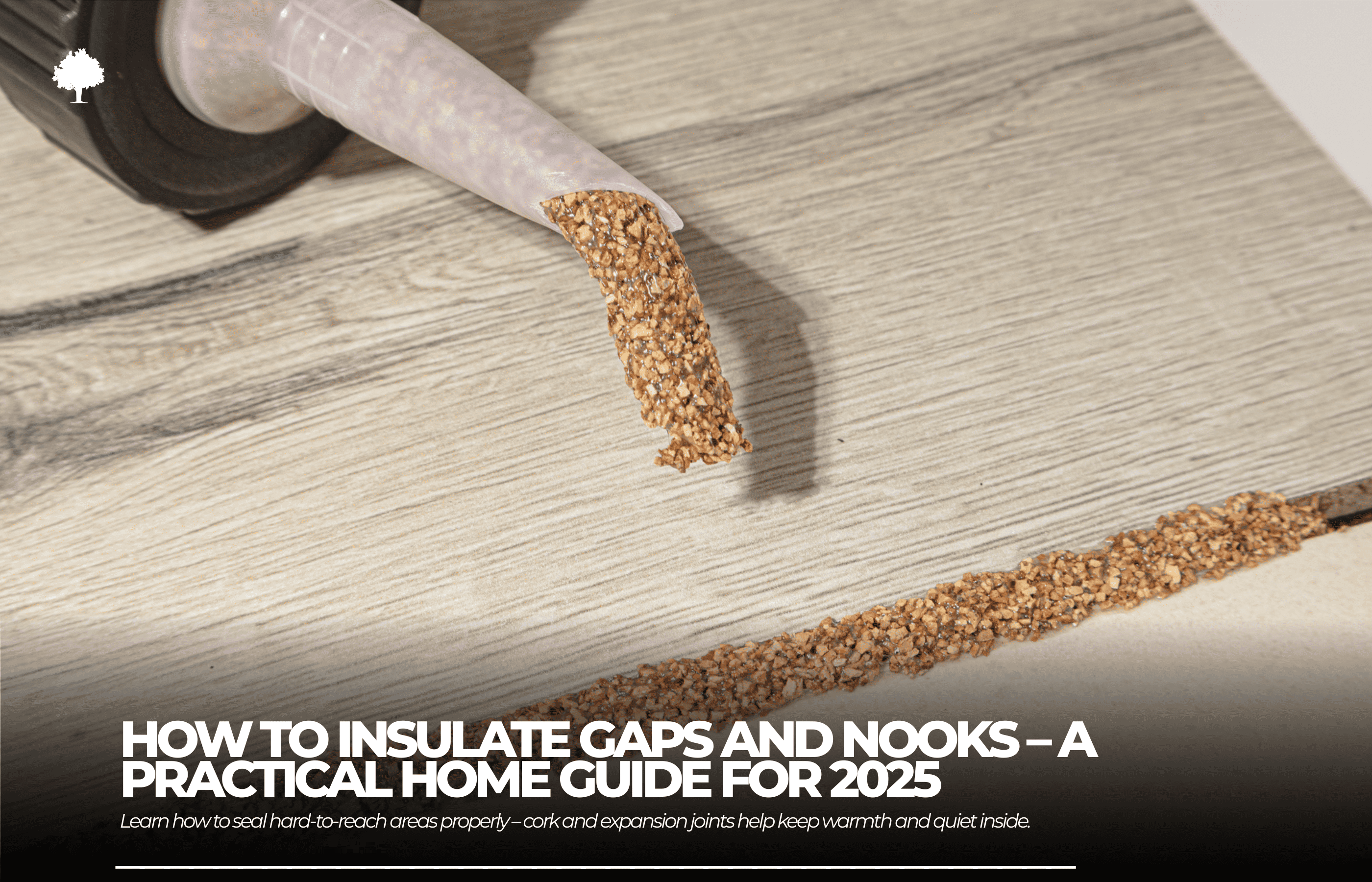

Filling recesses and gaps

The granules can be poured in or blown into hard-to-reach areas. Thanks to their structure, they adapt to the shape of the space and eliminate thermal and acoustic bridges.

Blown-in insulation between wall and floor layers

This is one of the most effective uses of cork granules. They can be applied as:

-

secondary insulation in older buildings (e.g., in cavity walls),

-

filling voids between floor beams.

Additive for mortars and screeds

Natural cork granules can be used as a lightweight natural filler for:

-

lime and cement mortars,

-

lightweight concrete,

-

dry mixes.

Summary

Insulating gaps, recesses, and hard-to-reach spaces is one of the biggest challenges in modern construction and renovation. While standard materials – such as polystyrene boards, mineral wool, or foams – work well on large, regular surfaces, their effectiveness drops sharply when faced with irregular spaces.

The solution lies in using a flexible, lightweight, natural material – expanded natural cork granules. Thanks to their structure, thermal and acoustic performance, as well as biological resistance and breathability, they are ideal as:

-

a filler for gaps and recesses,

-

a blown-in material between structural layers,

-

an additive for lightweight mortars and screeds.

Cork granules not only solve problems typical of difficult spaces but also meet the increasingly common need for eco-friendly, healthy, and durable construction materials. Their versatility makes them suitable for both modern energy-efficient buildings and the renovation of historic structures, where low weight and natural composition are especially important.

FAQ – Frequently Asked Questions

1. Are expanded natural cork granules suitable for any type of building?

Yes, cork granules can be used both in new buildings and in the renovation of existing – even historic – structures. Thanks to their low weight and natural origin, they work well in traditional, energy-efficient, and passive construction.

2. Does installing cork granules require specialised equipment?

It depends on the application:

-

For loose filling – no specialised tools are needed; a bucket, shovel, or simple manual pouring is enough.

-

For blown-in applications – pneumatic equipment is recommended (e.g., for insulating cavity walls).

-

For mortar and screed mixes – the granules are mixed manually or mechanically with a suitable binder (lime, cement).

3. Is the material resistant to moisture and mould?

Yes. Natural cork is inherently resistant to moisture, mould, and fungi. It does not permanently absorb water, and its structure allows the partition to “breathe”, preventing water vapour condensation.